01

Torsion Springs

What is a Torsion Spring?

A torsion spring is a coil spring that stores and releases rotational energy. Unlike compression or extension springs, torsion springs work by twisting along their axis. When a force is applied to one end of the spring, it causes the spring to twist, storing potential energy. When the force is removed, the spring returns to its original position, releasing the stored energy.

Properties of Torsion Springs

● Torque: Torsion springs produce a torque or rotational force when twisted. The torque produced depends on the spring's geometry, material, and the twist angle.

● Rate: A torsion spring's rate is the torque required to twist the spring through a specific angle. It is a measure of the spring's stiffness.

● Wire Diameter: The diameter of the wire used to make the spring affects its strength and flexibility. Thicker wire produces stronger springs, while thinner wire produces more flexible springs.

● Coil Diameter: The diameter of the coils in the spring affects its rate and deflection. Larger coil diameters generally result in lower rates.

● Number of Active Coils: The number of active coils in the spring affects its rate and deflection. More active coils generally result in higher rates.

● End Configuration: The ends of a torsion spring can be configured in various ways to meet specific application requirements. Common end configurations include straight, offset, and hook ends.

Applications of Torsion Springs

Torsion springs are used in a wide variety of applications, including:

● Automotive: Door hinges, hood supports, seat adjustments, and suspension systems.

● Appliances: Ovens, microwaves, refrigerators, and washing machines.

● Hardware: Door closers, garage door openers, and window balances.

● Medical devices: Surgical instruments, medical equipment, and prosthetics.

● Toys: Remote-controlled cars, action figures, and games.

● Industrial machinery: Conveyor systems, packaging equipment, and automation systems.

Torsion Spring Design and Selection

The design and selection of a torsion spring depend on several factors, including:

● Required torque: The amount of torque required to perform the desired function.

● Deflection: The amount of angular displacement required.

● Space constraints: The available space for the spring.

● Material: The material used for the spring, such as music wire, stainless steel, or phosphor bronze.

● Environment: The operating environment, including temperature, humidity, and corrosive conditions.

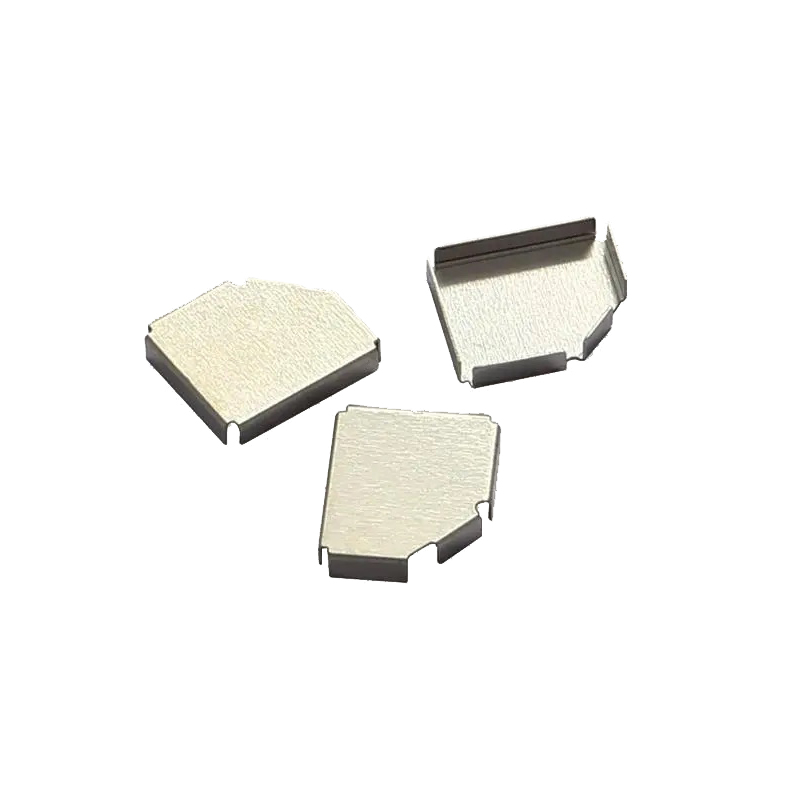

Custom Torsion Springs

Many manufacturers offer custom torsion springs to meet specific application requirements. Custom springs can be designed with various materials, end configurations, and coatings to optimize performance and durability.

Advantages of ShengYi technology

1.Perfect complete supply chain

Many years of factory experience have cooperated with various enterprises to develop a variety of products. Whether it is electroplating, electrophoresis, or post-processing, such as product coating, we have familiar suppliers within 30km of our factory.

So we can quickly make samples within 48 hours (Except for products that require surface treatment or testing)

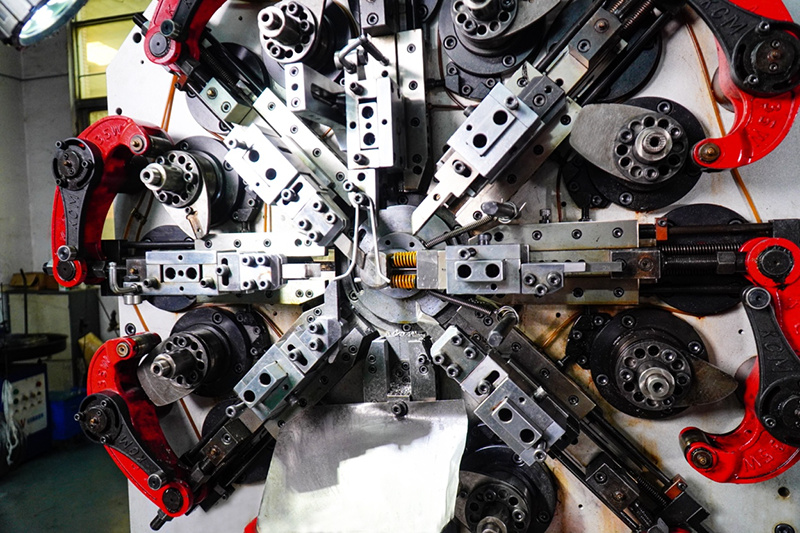

2. Rapid mass production

Once the sample is confirmed, production will be ordered immediately. The standard for mass production will be reached in 1-3 days.

3. Improve spring detection equipment

Spring testing machine: Used to measure the stiffness, load, deformation and other performance indicators of the spring.

Spring hardness tester: Measure the hardness of the spring material to assess its wear resistance and resistance to deformation.

Spring fatigue testing machine: Simulate the repeated load action of the spring under actual working conditions and evaluate its fatigue life.

Spring size measuring instrument: Accurately measure the geometric dimensions such as wire diameter, coil diameter, coil number and free height of the spring.

Spring surface detector: Detect spring surface defects, such as cracks, scratches, oxidation, etc.