01

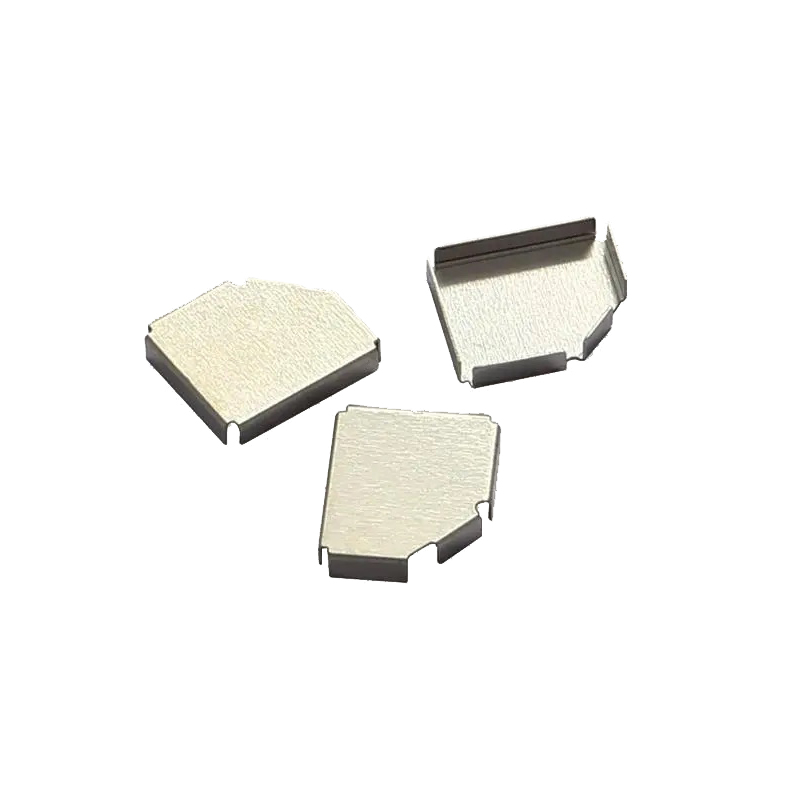

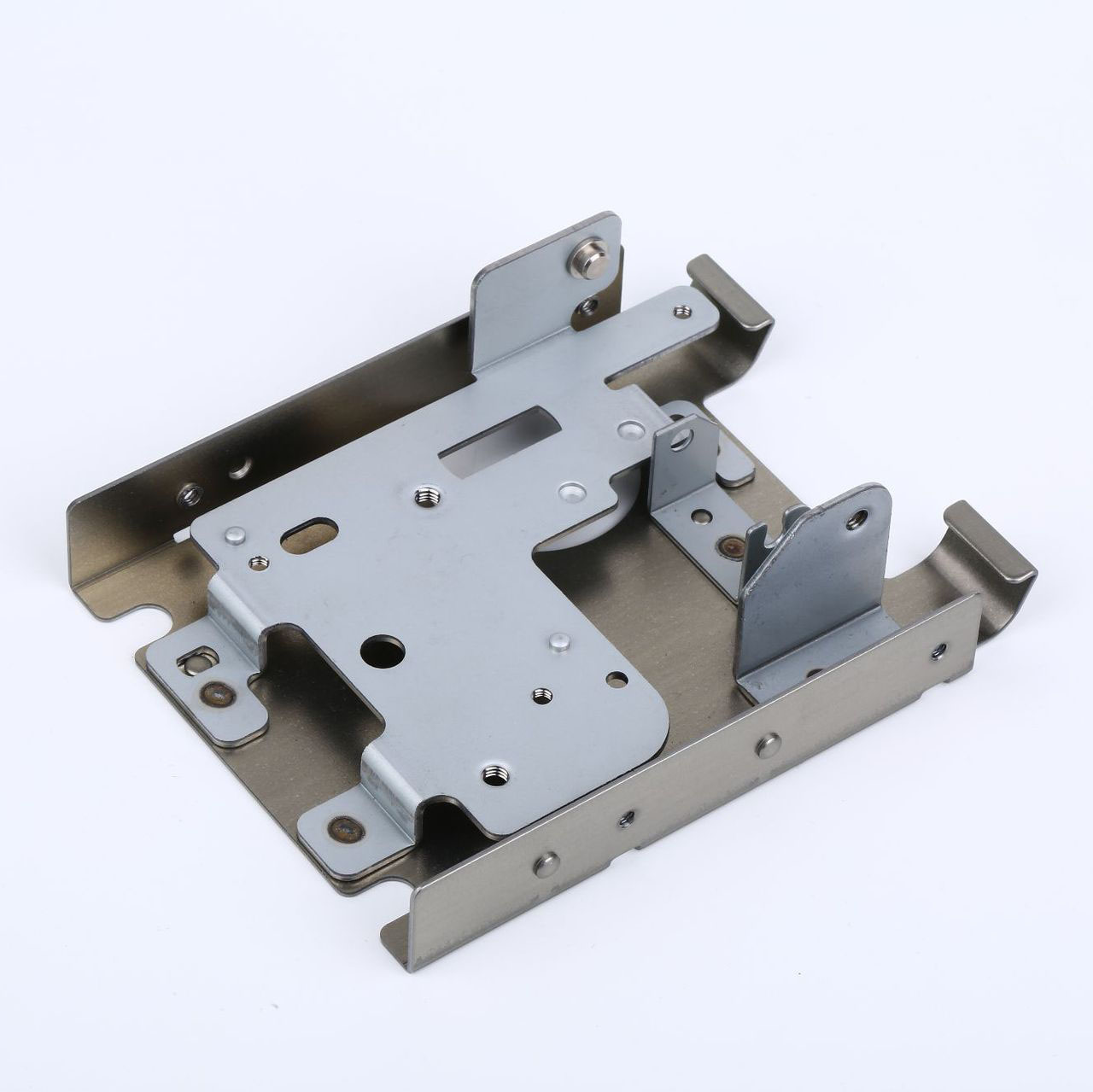

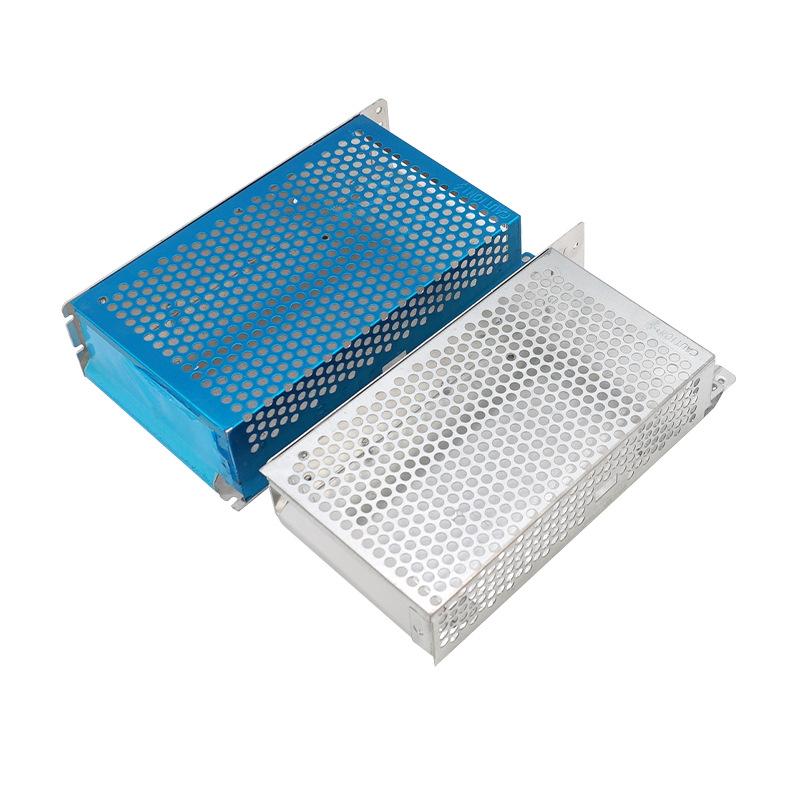

Metal Casing

What is a metal casing?

A metal enclosure is an enclosure made primarily of metal designed to enclose and protect internal electronic components, mechanical parts, or other items from external environmental factors such as shock, vibration, dust, and water. Metal casings are also known as metal boxes, metal casings or metal casings.

Metal shell manufacturing process

The most common manufacturing processes for custom metal enclosures are stamping and sheet metal fabrication.

●Stamping: This process involves using a stamping machine to apply pressure to a metal sheet to produce plastic deformation, thereby forming complex metal parts. Stamping has the characteristics of high production efficiency, high precision and low cost, and is suitable for the mass production of metal casings.

●Sheet metal processing: Sheet metal processing involves a series of processes such as cutting, bending, and welding of metal sheets to form metal parts with specific shapes and functions. Sheet metal fabrication offers greater flexibility in creating custom metal enclosures.

Advantages of metal casing

● Durable: Metal materials have excellent strength and rigidity, providing effective protection for internal components.

● Corrosion resistance: Through surface treatments such as powder coating or electrolytic polishing, the metal housing can have excellent corrosion resistance and extend its service life.

● Shielding: The metal shell can shield electromagnetic interference (EMI) and radio frequency interference (RFI) and protect the internal circuitry.

● Heat dissipation: Metal materials have good thermal conductivity and help dissipate heat.

● Aesthetics: Through surface treatments and coatings, metal casings can be made into various appearances to meet different aesthetic needs, such as brushed aluminium or stainless steel finishes.

Application of metal shell

The application range of metal housings is very wide, covering almost all industrial fields.

● Electronics: computer cases, server racks, industrial control enclosures, electronic equipment enclosures

● Electrical equipment: distribution boxes, control cabinets, instrument panels

● Communication equipment: telecommunications cabinets, network equipment enclosures

● Automotive industry: car casing, engine hood

● Mechanical equipment: industrial machinery casings, machine tool casings

● Medical Devices: Medical Device Enclosures

Material selection for metal casing

The choice of metal housing material depends on its application environment and performance requirements. Commonly used metal materials include:

● Stainless steel: It has excellent corrosion resistance and high-temperature resistance and is widely used in food processing equipment and pharmaceutical equipment.

● Aluminium alloys: lightweight, strong, easy to process, often used in aerospace applications and portable electronics.

● Galvanized steel: has good corrosion resistance and is relatively cheap, widely used for outdoor enclosures and general industrial applications.

Design and manufacturing of metal casings

The design of metal enclosures needs to consider factors such as functionality, aesthetics, cost and IP rating (ingress protection level). The design and manufacturing process uses advanced CAD/CAM technology to ensure product quality and customization.

We are a leading manufacturer of high-quality metal enclosures. We offer a wide range of custom metal fabrication services to meet your specific needs.