01

Flat Springs

What is Flat Springs?

As the name suggests, flat springs are springs with a flat cross-section. Flat springs offer excellent shape, size, and load capacity flexibility, unlike traditional coil springs. Their unique geometry allows for more complex designs and the ability to withstand higher loads in specific directions.

Classification of Flat Springs

Flat springs can be categorized based on their shape, function, and manufacturing process:

Shape:

● Rectangular flat springs: The most common type with a rectangular cross-section.

● Elliptical flat springs: Offering increased flexibility due to their elliptical shape.

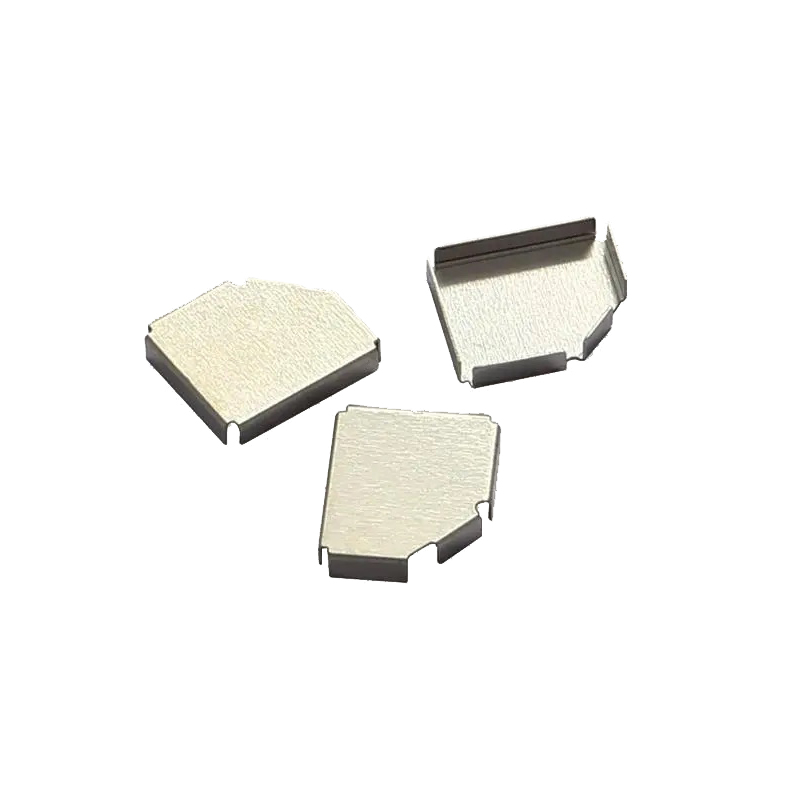

● Irregular flat springs: Custom-shaped springs designed to meet specific application requirements.

Function:

● Leaf springs: Widely used in automotive suspensions and other applications requiring high load-bearing capacity.

● Disc springs: Commonly used in valves, clutches, and other clamping applications.

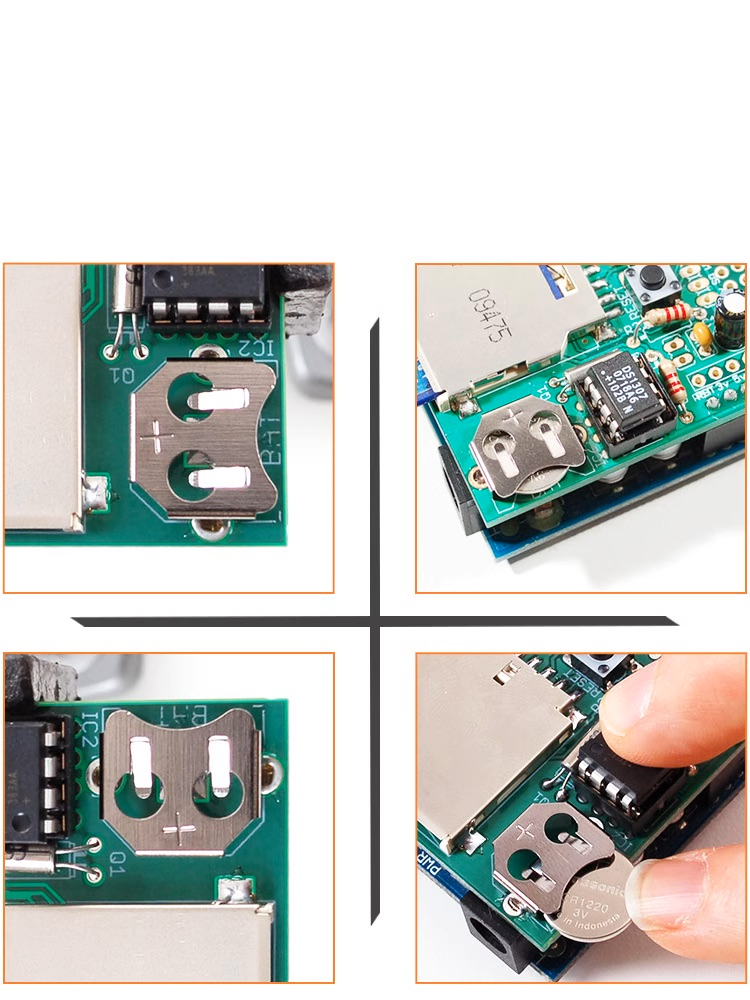

● Contact springs: Used in electrical connectors, switches, and relays.

Manufacturing Process:

● Stamping: The most common method involves stamping flat sheet metal into the desired shape.

● Laser cutting: Used for complex shapes and high precision.

● CNC bending: This is used to produce springs with bends and curves.

Materials Used in Flat Springs

The choice of material for a flat spring depends on the specific application and required properties. Common materials include:

● Carbon steel: Offers a good balance of strength and cost, making it suitable for general-purpose flat springs.

● Stainless steel: Provides excellent corrosion resistance and is often used in harsh environments.

● Alloy steel: Offers high strength, hardness, and wear resistance for demanding applications.

● Spring steel: Specifically designed for springs, providing high elasticity and fatigue resistance.

Materials Used in Flat Springs

The manufacturing process typically involves the following steps:

1.Material selection: Choosing the appropriate material and thickness based on design requirements.

2.Blanking: Cutting the material into the desired shape.

3.Forming: Bending or shaping the material using stamping, laser cutting, or CNC bending.

4.Heat treatment: Improving the material's properties through heat treatment processes.

5.Finishing: Applying coatings or treatments to improve corrosion resistance, appearance, or other properties.

Applications of Flat Springs

Flat springs find applications in a wide range of industries, including:

● Automotive: Leaf springs, clutch springs, and brake components.

● Electronics: Contact springs, switches, and relays.

● Aerospace: Aircraft components, landing gear, and control systems.

● Medical: Surgical instruments, implants, and medical device components.

● Industrial machinery: Clamps, hinges, and tensioning devices.

Design and Manufacturing Considerations

When designing and manufacturing flat springs, several factors must be considered:

● Load capacity: The spring must withstand the intended load without permanent deformation.

● Deflection: The amount of deflection required for the specific application.

● Material properties: The selected material must have mechanical and physical properties.

● Manufacturing process: The manufacturing process must produce the desired shape and tolerances.

● Cost: The cost of the spring must be competitive and within the budget constraints.

Advantages of ShengYi technology

1.Perfect complete supply chain

Many years of factory experience have cooperated with various enterprises to develop a variety of products. Whether it is electroplating, electrophoresis, or post-processing, such as product coating, we have familiar suppliers within 30km of our factory.

So we can quickly make samples within 48 hours (Except for products that require surface treatment or testing)

2. Rapid mass production

Once the sample is confirmed, production will be ordered immediately. The standard for mass production will be reached in 1-3 days.

3. Improve spring detection equipment

Spring testing machine: Used to measure the stiffness, load, deformation and other performance indicators of the spring.

Spring hardness tester: Measure the hardness of the spring material to assess its wear resistance and resistance to deformation.

Spring fatigue testing machine: Simulate the repeated load action of the spring under actual working conditions and evaluate its fatigue life.

Spring size measuring instrument: Accurately measure the geometric dimensions such as wire diameter, coil diameter, coil number and free height of the spring.

Spring surface detector: Detect spring surface defects, such as cracks, scratches, oxidation, etc.