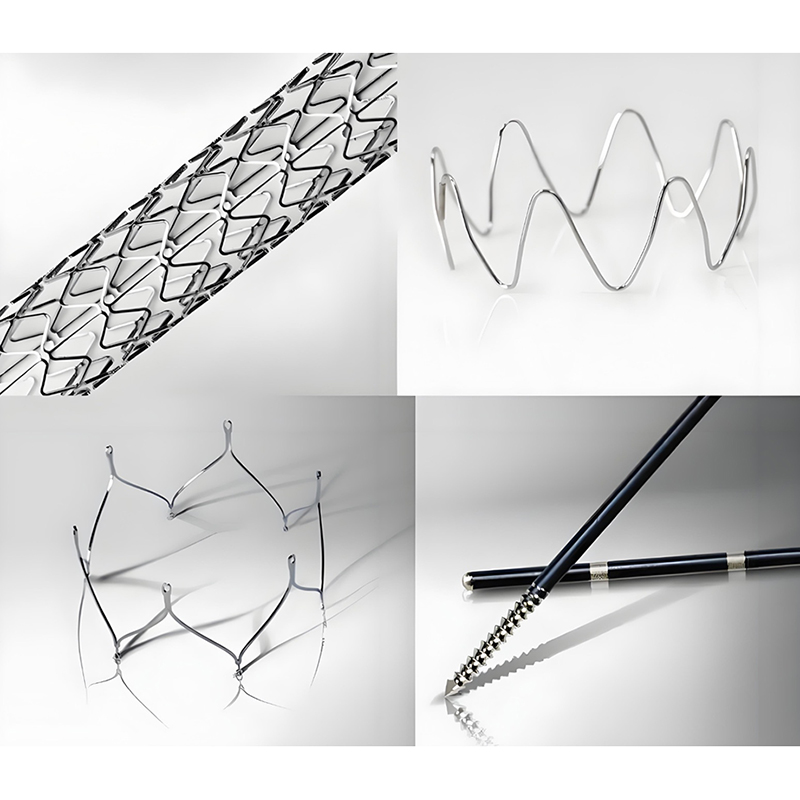

1. Cardiac stent:

Hauv kev phais plawv, Nitinol yog siv los ua lub plawv stents. Lub stent tuaj yeem raug compressed rau me me ntawm qhov kub thiab txias, tso cai rau nws yooj yim cog rau hauv cov hlab ntsha los ntawm kev phais me me. Thaum cov stent nkag mus rau tib neeg lub cev thiab cuam tshuam los ntawm lub cev kub, lub cim xeeb nyhuv ntawm nitinol ua rau nws rov qab mus rau nws cov preset stretched daim ntawv, yog li txhawb cov hlab ntsha phab ntsa thiab ua kom cov hlab ntsha qhib. Piv nrog rau cov khoom siv hlau ib txwm siv, cov nickel-titanium alloy stents hloov tau yooj yim dua thiab tuaj yeem hloov kho kom zoo dua qub rau cov hlab ntsha hauv lub cev thiab txo qhov tshwm sim ntawm cov teeb meem tom qab phais.

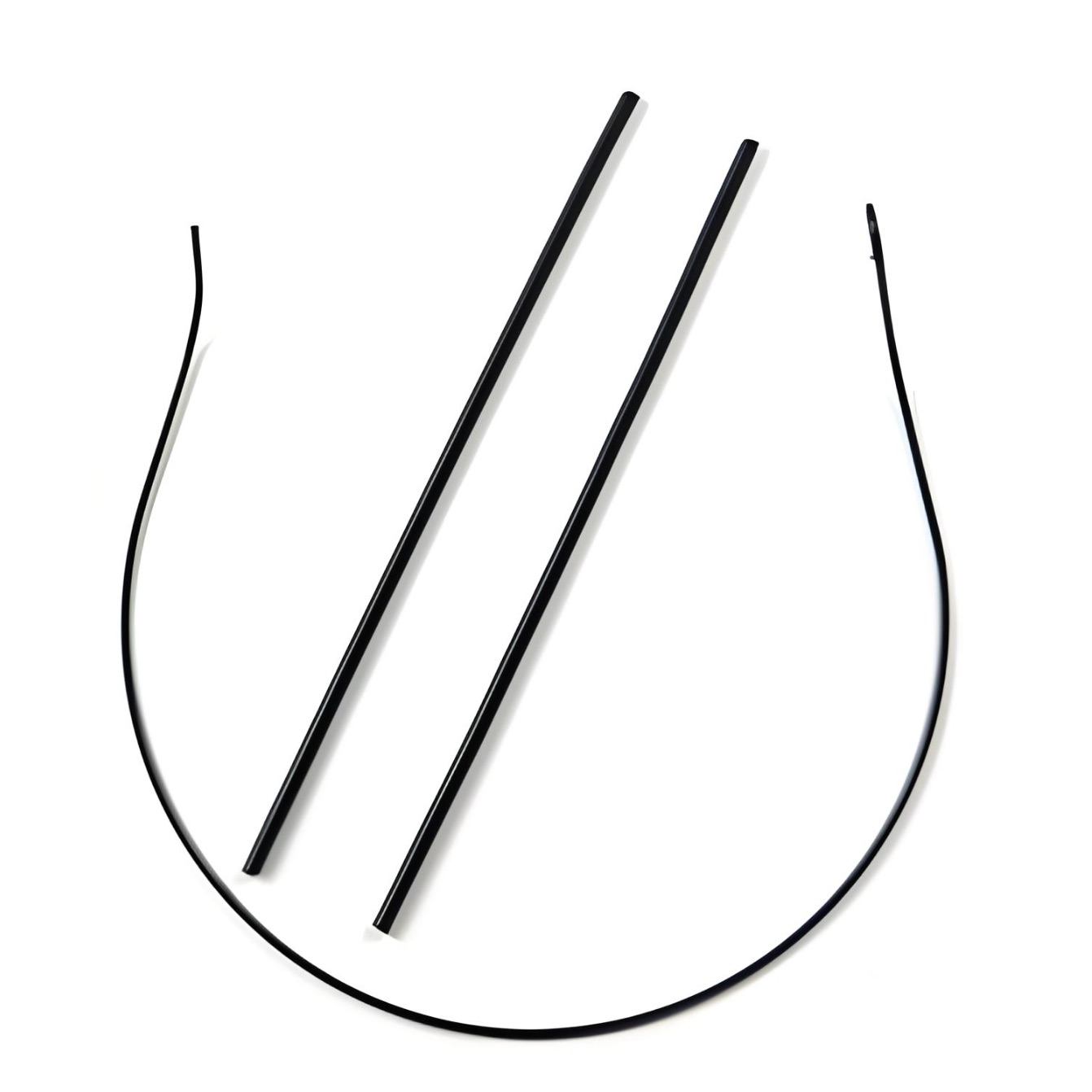

2. Orthodontics:

Nitinol yog dav siv nyob rau hauv orthodontics. Cov nickel-titanium alloy archwire siv los kho orthodontic tuaj yeem ua kom zoo dua ntawm nws cov txiaj ntsig kev nco thiab super-elastic zog kom tau txais kev kho nws cov duab raws li qhov kub thiab txias thiab siv zog kho kom zoo. Cov khoom no qhia tau hais tias zoo corrosion kuj nyob rau hauv lub qhov ncauj ib puag ncig, thiab nws cov elasticity siab ua rau cov neeg mob xis nyob, txo lub sij hawm kho, thiab txhim kho cov kev kho.

3. Qhov muag phais:

Nitinol yog siv nyob rau hauv kev tsim cov intraocular lens suspensions. Thaum lub sij hawm phais cataract, cov cuab yeej tuaj yeem cog rau hauv lub qhov muag siv cov tswv yim me me. Lub cim xeeb nyhuv ntawm npib tsib xee-titanium alloy tso cai rau nws tuaj yeem nthuav dav thiab kho lub lens thaum qhov kub thiab txias hloov, ua kom muaj kev phais meej thiab ruaj khov. Cov khoom siv biocompatibility ua kom nws txoj kev nyab xeeb mus ntev hauv lub qhov muag.

4. Aerospace:

Nyob rau hauv aerospace teb, nickel-titanium alloy springs yog siv nyob rau hauv cov khoom tseem ceeb xws li aircraft cav thiab tswj systems. Vim Nitinol's superelasticity, cov springs no tuaj yeem tiv taus kev vibrations thiab loj deformations thaum tswj lawv cov khoom qub tom qab ntau lub voj voog kev ntxhov siab. Qhov kev ntseeg tau zoo heev txhim kho lub neej kev pabcuam thiab kev nyab xeeb ntawm cov khoom siv dav hlau thiab txo cov nqi tu thiab sijhawm poob.

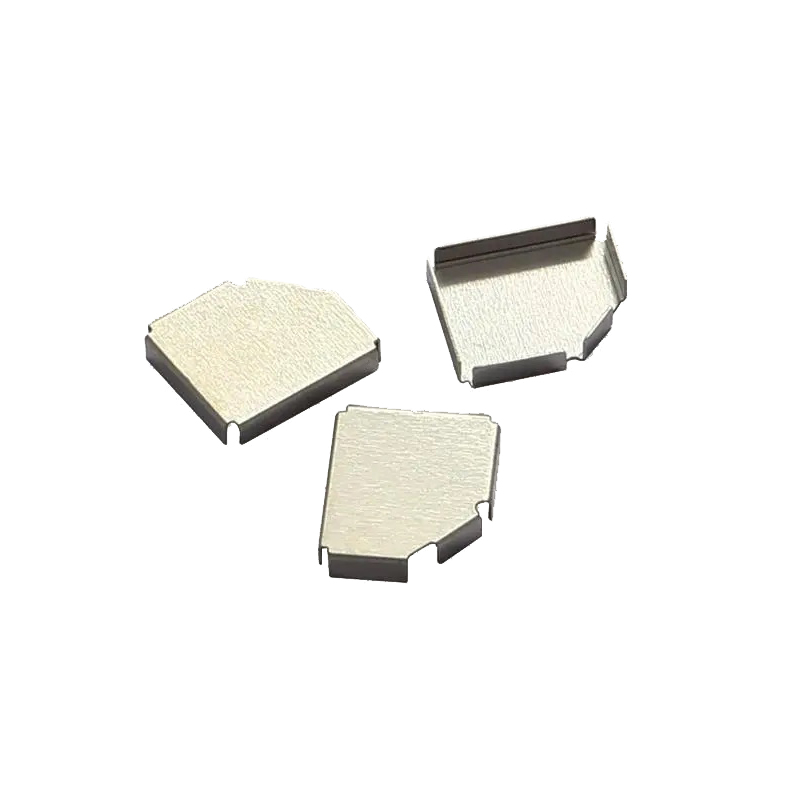

5. Cov khoom siv hluav taws xob:

Hauv cov khoom siv hluav taws xob, nitinol springs yog siv los ua cov khoom sib txuas thiab micro hloov. Nws super elasticity thiab durability xyuas kom meej tias lub connector muaj peev xwm tswj kev ruaj ntseg kev twb kev txuas kev kawm nyob rau hauv nquag ntsaws thiab unplugging thiab high-voltage ib puag ncig. Tshwj xeeb tshaj yog nyob rau hauv smartphones thiab wearable li, nitinol springs muab txhim khu kev qha cov neeg kho tshuab kev pab txhawb nqa thiab hluav taws xob kev twb kev txuas, txhim khu tag nrho cov kev ua tau zoo thiab durability ntawm lub cuab yeej.

6. Kev lag luam tsheb:

Nitinol springs yog siv nyob rau hauv automotive suspension systems thiab engine Cheebtsam. Nws cov elasticity siab thiab qaug zog ua haujlwm pab lub tsheb kom nqus tau cov kev vibrations thaum tsav tsheb, txhim kho kev nplij siab thiab kev nyab xeeb ntawm kev tsav tsheb. Nyob rau tib lub sijhawm, Nitinol qhov kev tiv thaiv corrosion ua kom muaj kev ruaj ntseg ntev ntawm cov khoom no hauv ntau qhov chaw hnyav thiab txuas ntxiv lub neej kev pabcuam ntawm lub tsheb.