01

Flat Springs

Flat Springs yog dab tsi?

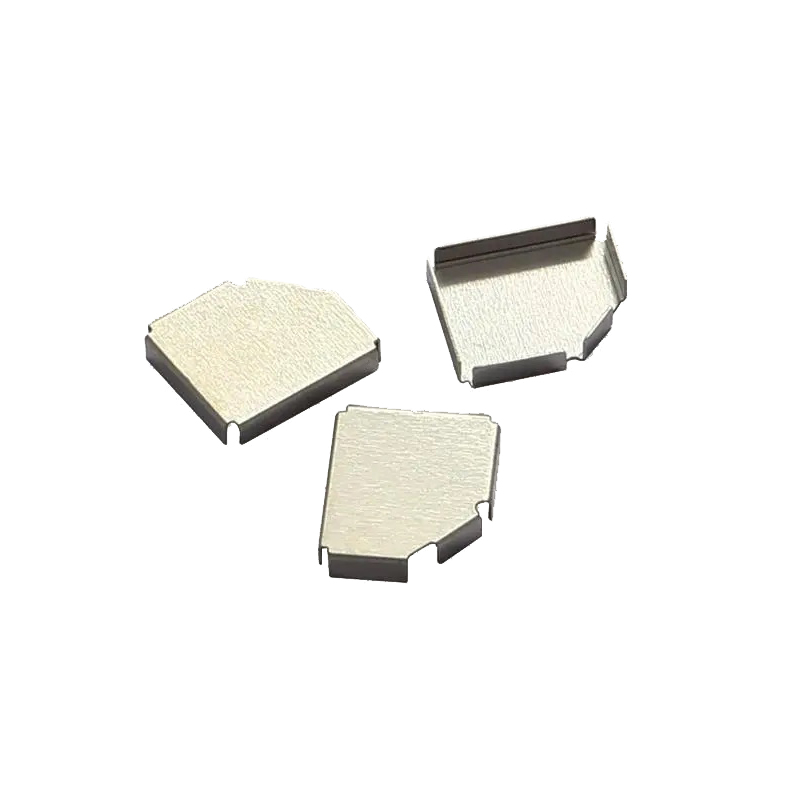

Raws li lub npe qhia, tiaj tus springs yog springs nrog ib tug tiaj tus cross-section. Flat springs muab cov duab zoo, qhov loj me, thiab lub peev xwm thauj khoom yooj yim, tsis zoo li cov coil springs. Lawv cov geometry tshwj xeeb tso cai rau cov qauv tsim ntau dua thiab muaj peev xwm tiv taus ntau dua hauv cov lus qhia tshwj xeeb.

Classification ntawm Flat Springs

Flat springs tuaj yeem raug cais raws li lawv cov duab, kev ua haujlwm, thiab kev tsim khoom:

Cov duab:

● Rectangular flat springs: Hom ntau tshaj plaws nrog cov duab plaub.

● Elliptical tiaj tiaj springs: Muab kev yooj yim dua vim lawv cov duab elliptical.

● Cov kab nrib pleb tsis sib xws: Cov khoom siv zoo li tus kheej tsim los ua kom tau raws li cov ntawv thov tshwj xeeb.

Muaj nuj nqi:

● Nplooj springs: Dav siv nyob rau hauv automotive suspensions thiab lwm yam kev siv uas yuav tsum tau muaj peev xwm load-bearing.

●Disc springs: Feem ntau siv hauv li qub, clutches, thiab lwm yam kev siv clamping.

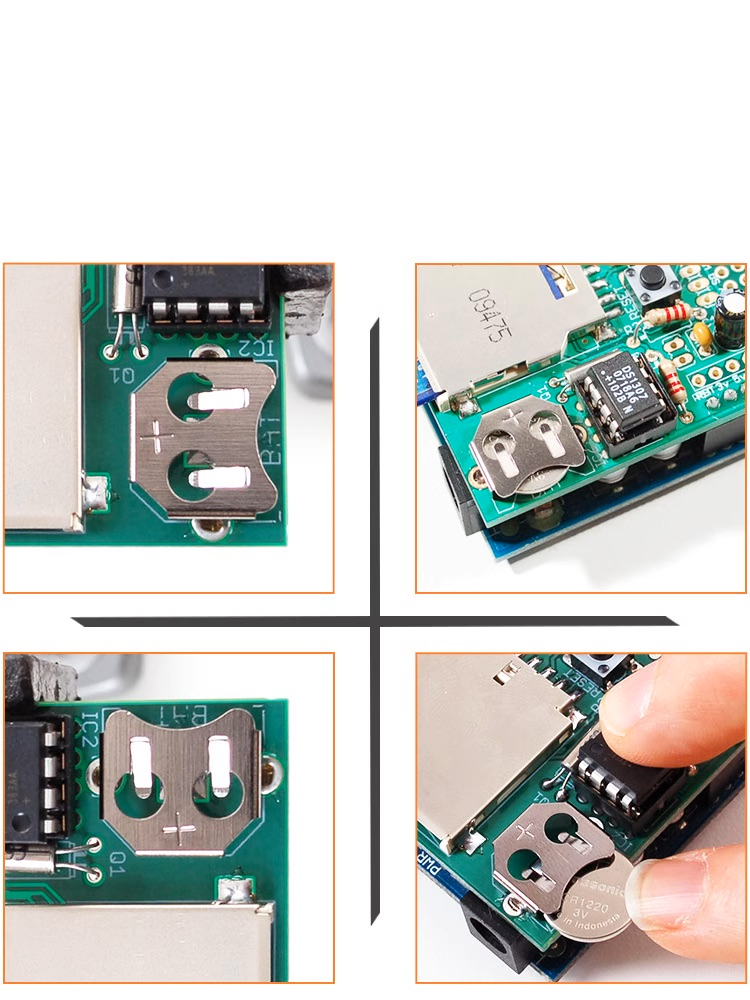

● Tiv tauj springs: Siv nyob rau hauv hluav taws xob connectors, keyboards, thiab relays.

Kev tsim khoom:

● Stamping: Txoj kev siv ntau tshaj yog stamping tiaj daim hlau rau hauv cov duab uas xav tau.

● Laser txiav: Siv rau cov duab nyuaj thiab siab precision.

● CNC dabtsi yog khoov: Qhov no yog siv los tsim cov springs nrog khoov thiab nkhaus.

Cov ntaub ntawv siv hauv Flat Springs

Kev xaiv cov khoom siv rau lub caij nplooj ntoos hlav tiaj tus nyob ntawm daim ntawv thov tshwj xeeb thiab cov khoom xav tau. Cov ntaub ntawv uas muaj xws li:

●Carbon steel:Muab qhov sib npaug zoo ntawm lub zog thiab tus nqi, ua rau nws haum rau cov hom phiaj dav dav.

●Stainless hlau:Muab kev tiv thaiv corrosion zoo heev thiab feem ntau siv hauv qhov chaw hnyav.

●Hlau alloy:Muaj lub zog siab, hardness, thiab hnav tsis kam rau kev thov.

●Caij nplooj ntoos hlav steel: Tshwj xeeb tsim rau springs, muab siab elasticity thiab qaug zog kuj.

Cov ntaub ntawv siv hauv Flat Springs

Cov txheej txheem tsim khoom feem ntau suav nrog cov kauj ruam hauv qab no:

1.Kev xaiv khoom: Xaiv cov khoom tsim nyog thiab tuab raws li kev tsim qauv.

2.Ncua tseg: Txiav cov khoom rau hauv cov duab uas xav tau.

3.Kev tsim: Khoov lossis shaping cov khoom siv stamping, laser txiav, lossis CNC dabtsi yog khoov.

4.Kev kho cua sov: Txhim kho cov khoom siv los ntawm cov txheej txheem kho cua sov.

5.Ua tiav: Siv cov txheej txheem los yog kev kho kom zoo dua corrosion, zoo li, lossis lwm yam khoom.

Kev siv ntawm Flat Springs

Flat springs pom cov ntawv thov hauv ntau qhov kev lag luam, suav nrog:

●Automotive:Nplooj springs, clutch springs, thiab brake Cheebtsam.

●Electronics:Tiv tauj springs, keyboards, thiab relays.

●Aerospace: Aircraft Cheebtsam, tsaws iav, thiab tswj systems.

●Kho mob: Cov cuab yeej phais, cov khoom cog, thiab cov khoom siv kho mob.

● Ikev lag luam machinery: Clamps, hinges, thiab tensioning devices.

Kev tsim thiab kev tsim khoom xav tau

Thaum tsim thiab tsim lub tiaj tiaj tiaj, ntau yam yuav tsum tau xav txog:

●Load peev:Lub caij nplooj ntoos hlav yuav tsum tiv taus qhov kev npaj thauj khoom tsis tas yuav deformation.

●Deflection:Tus nqi ntawm deflection xav tau rau cov ntawv thov tshwj xeeb.

●Khoom siv: Cov khoom siv xaiv yuav tsum muaj cov khoom siv kho tshuab thiab lub cev.

●Cov txheej txheem tsim khoom: Cov txheej txheem tsim khoom yuav tsum tsim cov duab uas xav tau thiab kam rau ua.

●Tus nqi:Tus nqi ntawm lub caij nplooj ntoos hlav yuav tsum muaj kev sib tw thiab nyob rau hauv cov nyiaj txiag txwv.

Qhov zoo ntawm ShengYi technology

1.Perfect tiav cov saw hlau

Ntau xyoo ntawm kev paub hauv lub Hoobkas tau koom tes nrog ntau lub tuam txhab los tsim ntau yam khoom. Seb nws yog electroplating, electrophoresis, lossis tom qab ua tiav, xws li cov khoom txheej, peb muajpaub cov neeg xa khoom hauv 30kmntawm peb lub Hoobkas.

Yog li peb tuaj yeem ua cov qauv sai sai hauv48 hnu(Tshwj tsis yog rau cov khoom uas xav tau kev kho saum npoo av lossis kev sim)

2.Kev loj hlob sai

Thaum cov qauv raug lees paub, ntau lawm yuav raug txiav txim tam sim ntawd. Tus qauv rau ntau lawm yuav ncav cuag hauv 1-3 hnub.

3.Txhim kho cov cuab yeej kuaj xyuas lub caij nplooj ntoos hlav

Lub tshuab kuaj lub caij nplooj ntoos hlav: Siv los ntsuas qhov nruj, thauj khoom, deformation thiab lwm yam ntsuas kev ua haujlwm ntawm lub caij nplooj ntoos hlav.

Caij nplooj ntoos hlav hardness tester: Ntsuas qhov hardness ntawm cov khoom caij nplooj ntoos hlav los ntsuam xyuas nws hnav tsis kam thiab tsis kam mus deformation.

Lub caij nplooj ntoos hlav qaug zog kuaj tshuab: Simulate qhov rov ua haujlwm ntawm lub caij nplooj ntoos hlav raws li kev ua haujlwm tiag tiag thiab ntsuas nws lub neej qaug zog.

Lub caij nplooj ntoos hlav loj ntsuas ntsuas: Ntsuas qhov ntsuas geometric qhov ntev xws li txoj kab uas hla, coil inch, coil tooj thiab qhov siab dawb ntawm lub caij nplooj ntoos hlav.

Caij nplooj ntoos hlav nto detector: Tshawb xyuas lub caij nplooj ntoos hlav defects, xws li tawg, khawb, oxidation, thiab lwm yam.